Detecting Cold Streaks in Specialty High-Gloss Paper

A new monitoring solution helps avoid build-up on calender rolls and damage to the paper processing system

A North American paper manufacturer was experiencing challenges with their specialty paper process. Wet coating streaks were causing build-up on the roll covers, damaging the surface and costing the plant $1M USD annually per machine in unplanned downtime, maintenance, and lost production. Optical cameras weren’t sensitive enough to detect the subtle changes in sheet characteristics and moisture content associated with streaks.

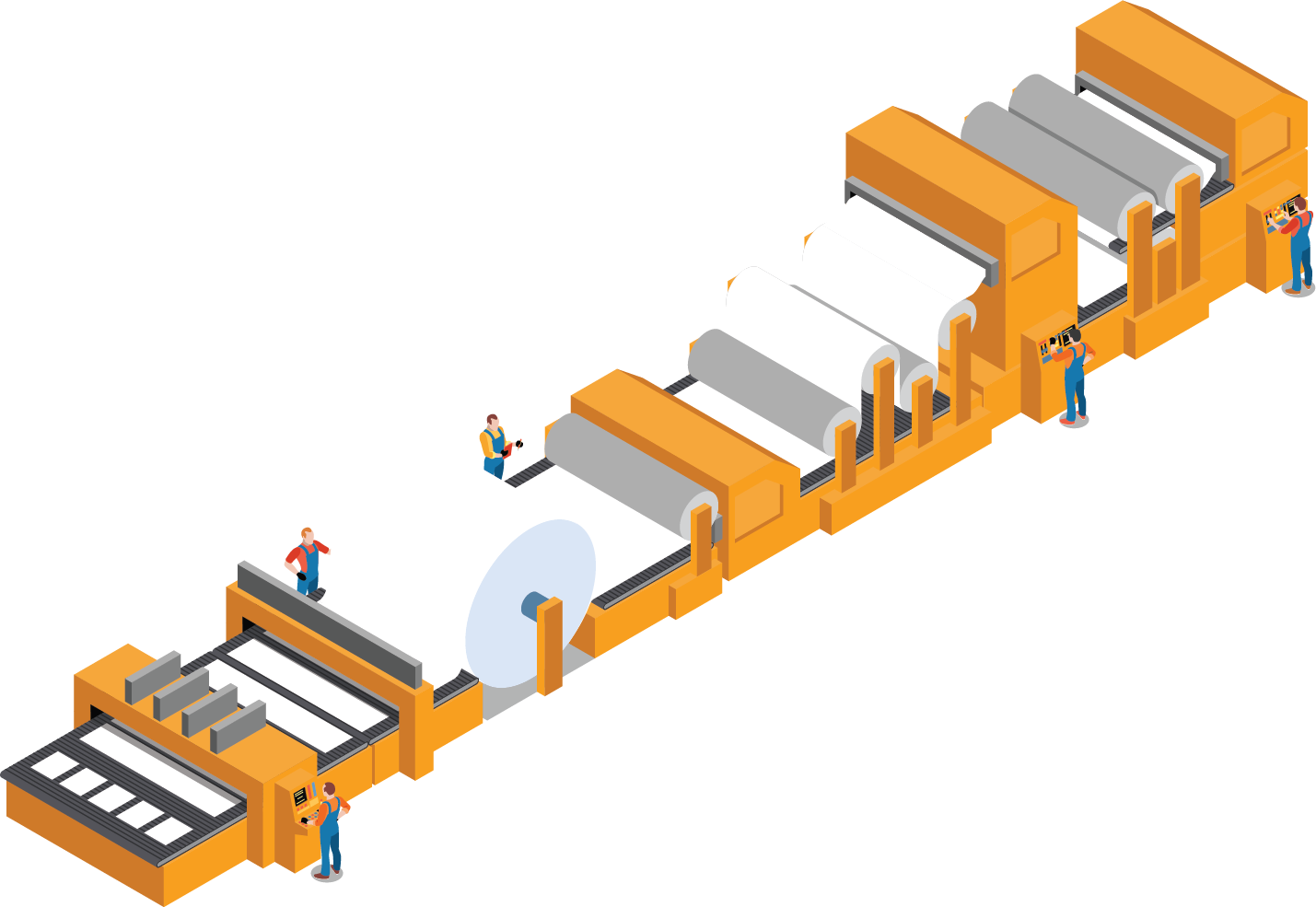

Calendering is an important part of the process where paper thickness and finishing is refined before rolls are cut and distributed. Excess moisture on the web can lead to build-up on the roll that cuts the thin rubber surface. Events occur within 7-10 seconds and cost up to $100,000 USD in damage and lost production per event. The plant operates three paper machines (A, B, and C) with optical cameras installed on machine B to identify holes in the sheet. Optical cameras, however, cannot detect the subtle changes in temperature associated with coating streaks, leaving the system vulnerable to damage.

Figure 1: Calender machine used during paper production

DETECTING COATING STREAKS

A set of thermal cameras installed prior to the calendering section on all three paper machines continuously inspects the full width of the sheet. An Edge computing device installed on each machine efficiently processes real-time image and video data as well as all machine sensor data. Immediately after installation, Eigen’s solution begins capturing detailed temperature profiles of the web before it enters the calendering machine. Cold streaks indicate excess moisture so basic temperature limits are set to enable realtime alarms on the plant floor.

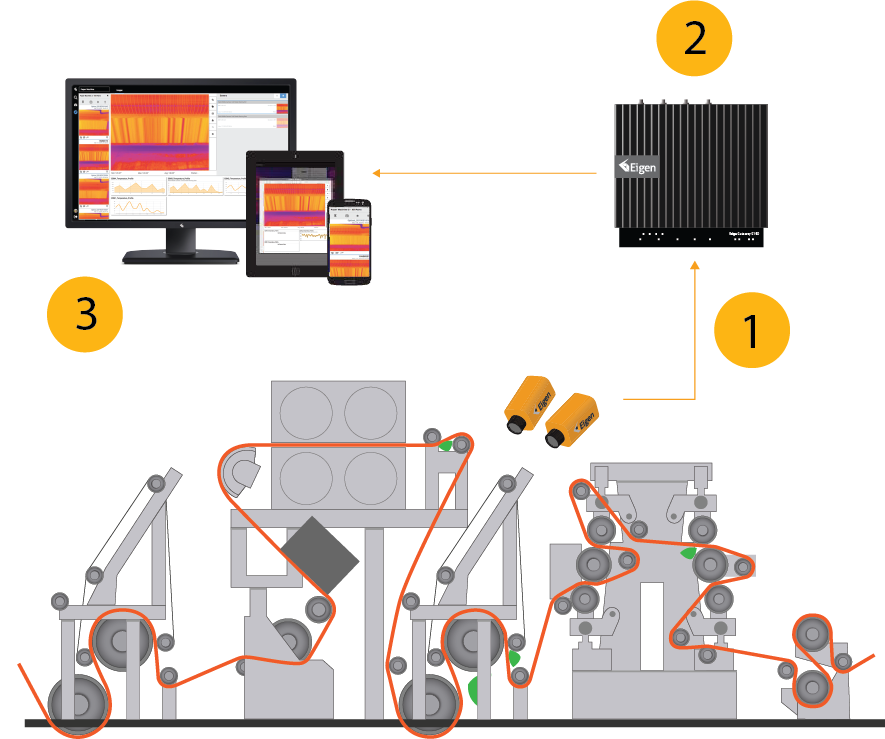

Figure 2: The Eigen installation. 1) Advanced thermal imaging continuously monitors the sheet. 2) Edge Device seamlessly aggregates data from cameras, PLCs, and SCADA systems. 3) Real-time alarms on the factory floor and analytics platform.

ENABLING AUTOMATIC PRESSURE REDUCTIONS

Following a trial period to refine the algorithm and ensure accuracy, communication to the machines’ respective PLCs is enabled. Calender stacks are automatically opened upon detection of cold streaks allowing operators to clean the roll covers and prevent surface damage. The system also allows for more detailed analysis of temperature profiles, images, videos, and machine sensor data through the platform for troubleshooting and root cause investigations.

Figure 3: Screenshot of real-time temperature profiles

THERMAL MONITORING LEADS TO COST SAVINGS

Prior to installation, the manufacturer experienced an average of 30 excess-moisture events annually, at a cost of $100,000 per event or $3.0 M each year. With the installation of the new monitoring system, Eigen estimates they will experience zero events; instead, the unload alarms will lead to approximately 300 unloads for a total savings of $1.2 M. These savings are estimated based on the total costs associated with events (damaged calender rolls requiring replacement) including unplanned, downtime, repairs, maintenance, and lost production. Costs associated with unload alarms are calculated based on an average of 5-15 minutes of production of off-spec paper per unload due to roll cover cleaning by operations.

Learn more about thermal imaging cameras or this application: FLIR.com/instruments/manufacturing