HFC Detection Using Optical Gas Imaging Increases Safety & Efficiency While Reducing Emissions

By Craig O’Neill, Teledyne FLIR

and Ryan A. Cochran, Chemours Company

While the oil-and-gas industry has benefited greatly from the use of optical gas imaging (OGI) cameras—improving worker safety and plant efficiency while reducing emissions—the technology has yet to gain a similar foothold in the petrochemical industry, despite offering similar advantages. Comfort with existing gas-detection methods and a lack of familiarity with the full capabilities of OGI cameras often act as barriers to the latter’s implementation. However, with commercial hydrofluorocarbon (HFC) gas emissions now under increased scrutiny by the U.S. Environmental Protection Agency (EPA) and other global regulators, there is more impetus for HFC producers and industrial HFC users to deploy new and emerging technologies to ensure mechanical integrity of their processes and equipment.

Many well-prepared companies already have environmental, social, and governance (ESG) programs driving sustainability, including initiatives tied to emissions reduction. Still, continued use of ambient air monitoring utilizing Fourier transform infrared (FTIR), supplemented by handheld leak detectors, is only a partial solution to the need for more comprehensive industrial monitoring—especially as regulators begin to employ state-of-the-art instrumentation themselves.

This incumbent system of leak detection has several constraints that need to be understood by industrial practitioners. On-demand point leak detection generally takes place either during routine maintenance or when an FTIR ambient monitor alarm is triggered by a possible gas leak. A production operator with appropriate personal protective equipment (PPE) must then be positioned close to the leak source to confirm its existence using a handheld refrigerant leak detector (also called a toxic vapor analyzer, organic vapor analyzer, or “sniffer”).

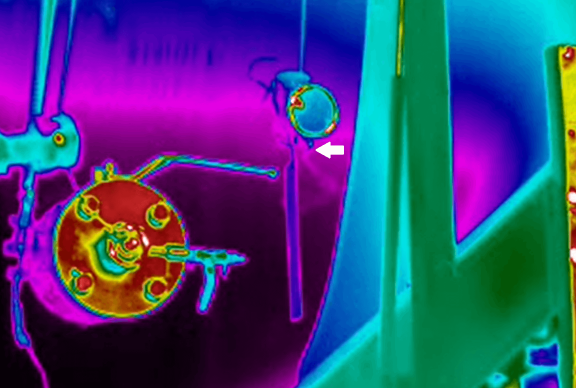

Figure 1: Leak identified on a pressure gauge fitting using a GF304 OGI camera, visually conforming the leak did not originate from a manual vapor valve, as originally believed.

A handheld vapor analyzer may not be able to accurately identify the leaking component—key when repairing or understanding the challenges associated with a leak. The emission source may also be in a difficult-to-access location, making leak confirmation with a handheld detector difficult or even impossible.

OGI cameras are able to detect leaks from a safe distance as well as identify leaks in locations or volumes that otherwise would not be discovered. These cameras supply visible confirmation of emissions, versus a vapor analyzer whose reading could vary from one minute to the next depending on environmental conditions, even when sampling in the exact same location. Meeting the industry’s demand for more precise, safer refrigerant leak detection, Teledyne FLIR offers OGI cameras that satisfy a range of use scenarios, from pinpointing difficult-to-find leaks to identifying different gases with a single device.

Figure 2: The FLIR GF304 cooled OGI camera and the GF77 uncooled OGI camera used to identify HFC-leaking components.

The FLIR GF304 is the industry’s only cooled OGI camera filtered specifically to detect fluorocarbons. In addition to visualizing refrigerant leaks precisely from a distance, the GF304 can accurately measure temperatures, allowing users to note temperature differentials and improve visual contrast for better gas plume detection (Fig.2).

The FLIR GF320 detects hydrocarbon and volatile organic compound (VOC) emissions from natural gas production and use. With this optical gas imaging camera, inspectors can check thousands of components and see potential gas leaks in real-time. The GF320 is lightweight, offers both a viewfinder and LCD monitor, and has direct access to controls. Embedded GPS data helps in identifying the precise location of faults and leaks, for faster repairs.

The FLIR GF77 is an uncooled OGI camera with interchangeable lens options capable of detecting fluorocarbons, methane, sulfur hexafluoride (SF6), and other gas emissions. While not as precise as the HFC-focused GF304, the GF77 offers lower-cost utility to users hunting different types of gas leaks (Fig. 2).

Petrochemical Industry Leader Embraces New Detection Technology

Chemours, a global manufacturer of advanced materials for critical applications such as semiconductor manufacturing and clean energy, as well as thermal management solutions for automotive, cold chain, and air conditioning, was introduced to OGI technology by a European third-party that provides on-demand site surveys using the OGI technology. In 2019, Chemours adopted OGI as a component of its mechanical integrity and reliability programs and purchased the first set of cameras—a GF304 for fluorocarbon gas detection and a GF320 for natural gas leak detection.

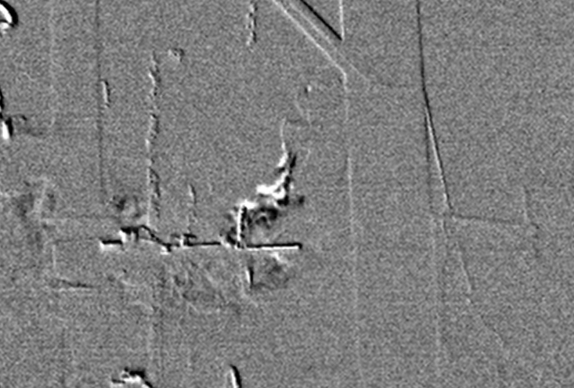

Figure 3: Overhead leak found on a pipe bridge with a FLIR GF304 OGI camera. This leak would not have been identified using traditional leak detection technologies.

Building on the success of the European adoption of OGI technology, Chemours began working with the cameras at its US sites in early 2021.Chemours—eager to bolster its leak detection capability—organized a demonstration of the FLIR GF304 at a major manufacturing facility. Technical personnel from across the site gathered for the hour-long presentation before the vendor placed the camera in the hands of Ryan Cochran, a Process Analyzer Staff Engineer at the site.

Over the course of the first day of use, the OGI technology proved its value by precisely locating opportunities for maintenance and inspection that were not previously possible. This initial positive trial and equally productive subsequent days of monitoring have led to both acceptance of the technology and a return on the investment for the camera. Based on the success of the demonstration, the plant manager approved the purchase request for the first camera at that site and a GF304 has been in use since April 2021.

Cochran developed a keen interest in the OGI technology and has quickly become the Chemours subject matter expert in that area of work. He is committed to providing site operators the best tools possible to inspect and maintain process equipment and respond to any on-demand maintenance indications that arise. OGI offers distinct and demonstrated advantages for those operators that include fewer false positive detections and more precise location of areas of concern.

Figure 4: Comparison of the same leak in Normal Mode (top) and High Sensitivity Mode, or HSM, (bottom). The HSM feature, combined with proper training, enables an OGI user to inspect smaller leaks more easily.

Cochran was then tasked with showcasing the OGI camera’s capabilities at other sites. He combined real-world usage examples with additional product information to share with Chemours’ corporate Instrument Reliability Network group (i.e., an interorganizational team that evaluates new technologies—also called an innovation division at some companies).

Several types of leaks were among the training examples used to introduce OGI to his Chemours colleagues:

- Pipe Bridge Leak—This “up-in-the-air,” pinhole-sized leak was discovered in piping (not on connection point) transferring finished product into a storage tank during a periodic shutdown maintenance activity. The leak would not have been found using an ambient air tester or a handheld analyzer (Fig. 3). Its discovery and subsequent repair eliminated a safety hazard, an out-of-compliance emission, and a direct loss of profit. One of the benefits of OGI is the ability to quickly validate mechanical integrity after a site-wide maintenance shutdown. The sensitivity, precision, and portability of the camera allows for a very efficient series of inspections and the time savings is significant.

- Truck-Loading Leaks—Leaks created when connecting hoses to trucks to transport product generally are not identified or gauged, resulting in incalculable losses between how much product a company may produce versus how much is actually loaded and shipped. OGI cameras help organizations improve worker safety during loading while also helping them better understand the product loss and increase return on investment (ROI).

- Incorrectly Recorded Leaks—A leak identified with a handheld analyzer was to be confirmed with an OGI camera. The camera operator determined the handheld analyzer had misdiagnosed the leak location. Had the leak been incorrectly tagged, a $5,000+ repair would have been executed—emptying the trailer and replacing the incorrect component needlessly. Using OGI, the leak was correctly tagged and the correct component replaced, avoiding the need to empty the trailer and ensuring safer work conditions.

Cochran said he visited several Chemours sites with both the GF304 and the GF77. At each location, he introduced the plant manager to the camera, provided some rudimentary training, and let the devices‘ capabilities speak for themselves. Demonstrating the effectiveness of the OGI cameras leads to rapid adoption by local mechanical integrity teams.

In order to maintain training currency and consistency in the use of the technology, a site OGI lead is identified. This local resource works closely with Cochran to maintain OGI as global program that is standardized across sites. A team of 4-6 internal technicians is also identified to use the cameras for planned maintenance with an eye toward leak prevention. This approach and team structure enhances mechanical integrity, reliability, and leak detection and repair programs with the capability to be more proactive and timely.

Several operators per shift are trained to use the GF77, providing them a more effective means to find leaks whose general location is known due to an FTIR alarm. OGI provides surety to that investigation, whereas the use of a handheld analyzer can require more time and still not yield localized leak sources. In addition, the GF77 offers the utility to find natural gas leaks (e.g., from on-site furnaces).

Final Thoughts

While OGI cameras provide the petrochemical industry with a powerful addition to the corporate leak detection toolbox, their effective use requires proper training. Many different variables can affect measurement, from ambient air temperature behind the leak and the angle of measurement to the color palette applied and the distances from which you measure. Ultimately, experience is the best teacher. The rewards for an investment in OGI cameras though, are difficult to overstate. Worker safety is improved by providing confidence in predictive maintenance, proactive inspections, and repair validation. Manufacturing organizations can also have confidence in their ability to meet corporate ESG goals.