Top 10 Questions: Gas Leak Quantification with OGI Cameras

Common questions about quantitative optical gas imaging from FLIR include environmental effects on operation, regulatory concerns, and technological improvements on the horizon.

By Craig R O’Neill, FLIR

This article examines common questions and concerns surrounding quantitative optical gas imaging (qOGI). More specifically, it answers 10 questions related to the use of FLIR’s QL320 platform, which pairs new technology – in the form of a ruggedized plug and play tablet -- with FLIR’s existing GF320, GFx320, and GF620 OGI cameras to quantify hydrocarbon gas leaks in units of mass leak rate, volumetric leak rate, or concentration over pathlength.

This article’s subject matter builds on the previous piece in this series, which introduces qOGI systems, discussing their functionality and advantages over competing technologies.

Read the story below or download the pdf

IS QOGI CURRENTLY USED AS A REGULATORY ENFORCEMENT TOOL?

Currently, no U.S. regulatory driver exists for qOGI methods. As industry operators strive to be more responsible stewards of the environments in which they operate, qOGI is used to conduct field studies and determine emissions for internal purposes, leaving each company free to determine the benefits of qOGI and to deploy it accordingly.

HAS THE QOGI METHOD BEEN VETTED?

QOGI is an emerging technology, in development since 2014, and it has been subjected to extensive validation testing, including blind testing with known release rates. Some of the publicly available testing results include:

- A test performed by the EPA in Research Triangle Park, quantifying methane and propane leaks.

- An Oil and Gas industry leader field test comparing the qOGI method to the Bacharach Hi Flow® Sampler (BHFS). QOGI achieved +/- 30 percent accuracy over several weeks of blind testing comprising dozens of test points across different gases (including produced gas), spanning a wide range of backgrounds and environmental conditions.

- A study conducted by a European industry group – which includes most of the oil companies operating in Europe – dedicated to researching environmental issues relevant to the oil industry. This study concluded that qOGI significantly outperforms U.S. EPA Method 21 in terms of result accuracy.

NOTE: Both the oil and gas industry leader and European Concawe studies were sponsored by industry.

THE FLIR QL320 ASKS YOU TO SELECT ONE GAS TO QUANTIFY. WHAT IF THE GAS STREAM CONTAINS MULTIPLE COMPOUNDS?

It bears mention that the U.S.’ EPA-approved Method 21 shares this limitation; where qOGI shines is in how it addresses this uncertainty.

Using a flame ionization detector (FID) under Method 21, you typically calibrate the device to a pure gas, then measure process streams. The gas composition can change the FID response significantly but, generally, this error is accepted, even though it can introduce an error of 200 percent or more to Method 21. Most facilities don’t calibrate their FID to each specific process stream (a corrective action); they simply accept the concentration number (measured as a pure calibration gas). Method 21 offers no recourse to retroactively adjust the result.

The FLIR QL320 makes it easy to correct for the gas mixture and adds flexibility to the task. Further, the correction is fundamental, meaning it is not dependent on the specific instrument (as with an FID and Method 21). The FLIR QL320 allows users to adjust for the gas mixture after the fact, and your adjustment will be applicable to any FLIR QL320 result applied to that process stream, on any given day or environmental conditions.

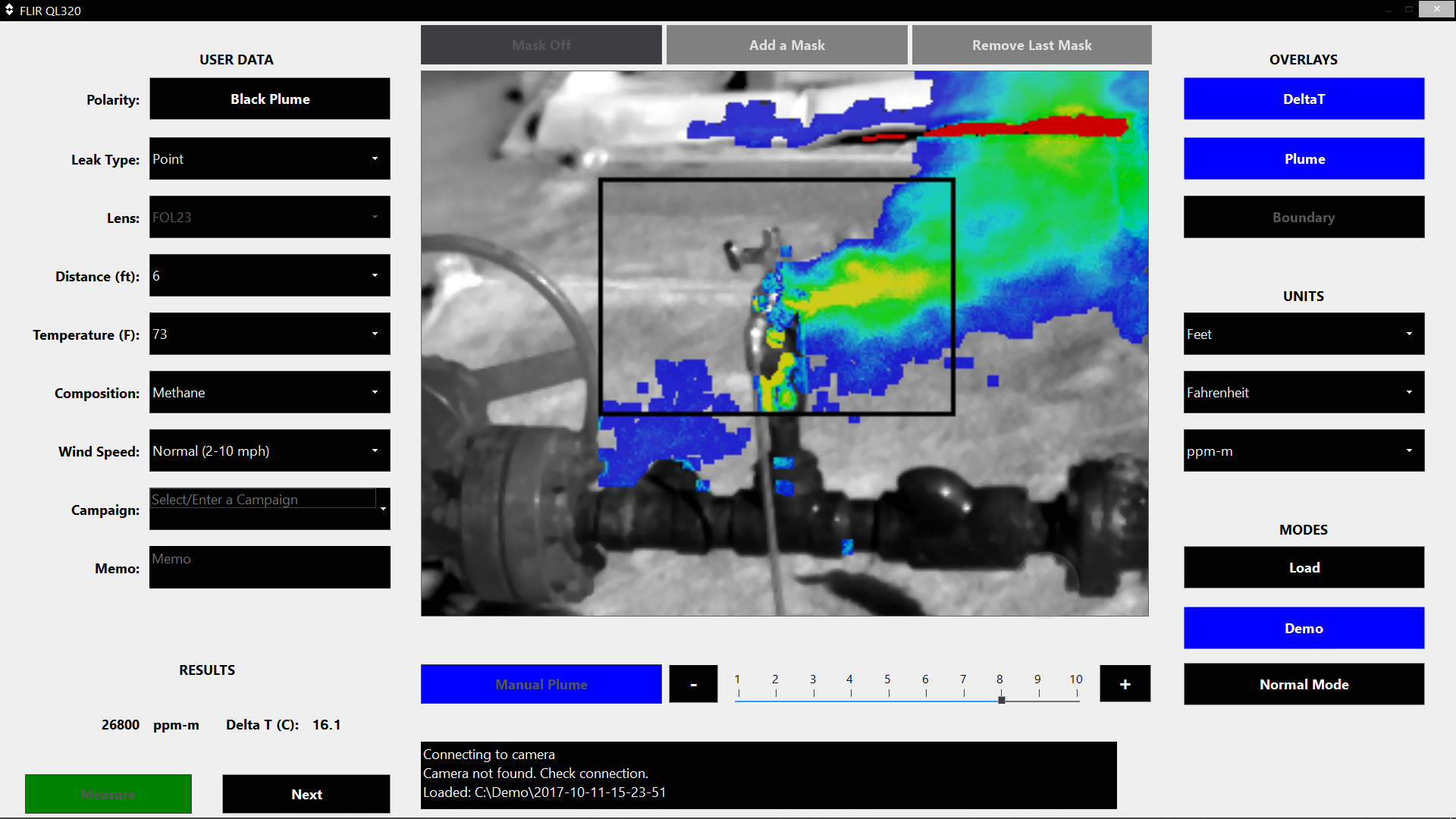

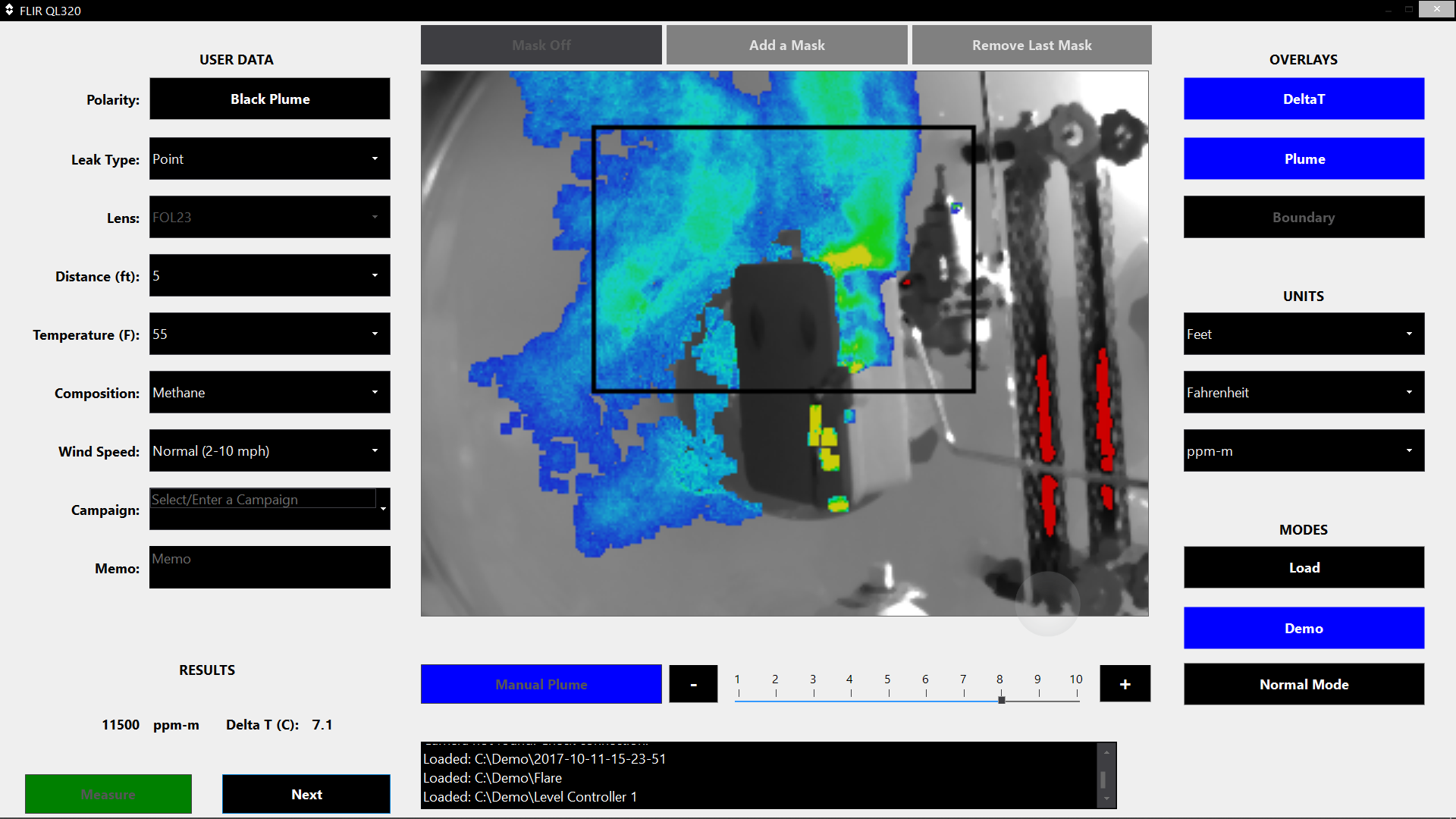

FLIR QL320

FLIR QL320

HOW WILL ENVIRONMENTAL FACTORS AFFECT MY MEASUREMENTS?

Delta temperature (ΔT) comprises the greatest factor affecting accurate qOGI. There must exist sufficient temperature differential between the ambient temperature adjacent to the gas plume and the background.

While capturing video with the tripod-mounted OGI camera, QL320 users will need to ensure the highest ΔT possible. At a minimum, you’re seeking 2°C of difference in temperature between the ambient air near the gas leak and the apparent temperature of the background in the image.

Most wind conditions will not be detrimental to qOGI accuracy. If no wind is present, leaking gas may not reliably flow in one direction, leading to “pooling” of the gas. Conversely, high winds (e.g., greater than approximately 15 MPH) create challenges because the wind sweeps gas away from the release point so quickly. That said, most gas leaks will fall within an acceptable wind speed range or occur in a shielded or partially shielded location.

Wind is input into the FLIR QL320 at three levels (Calm, Normal, and High). The result is more consistent in higher wind speeds (where no gas plume pooling takes place). Accuracy is within 30 to 40 percent.

Humidity has no effect on the system’s measurement capability.

WHAT ARE THE MINIMUM AND MAXIMUM SIZE LEAKS THAT CAN BE SUCCESSFULLY QUANTIFIED WITH THE FLIR QL320?

The minimum size of a leak that can be quantified is a function of the ΔT (between ambient temperature near the gas and the background), the compound you are imaging, and the wind speed. FLIR’s QL320 system has demonstrated the ability to quantify propane leaks down to 100 scc/min and methane leaks down to 300 scc/min with a ΔT of 5°C and a moderate wind speed.

A good general rule: if you can see the leak in normal mode, the system most likely can quantify it. If you must use high-sensitivity mode to see the leak, the FLIR QL320 may struggle to quantify it accurately.

For maximum leak rates, the current model is calibrated with propane from 0.1 l/min to 30 l/min. We could safely extend this to 2x or 3x the calibrated range, or 100 cc/min up to 100 l/min (for propane). For methane, we would have correlated boundaries at 300 cc/min to 300 l/min.

FLIR QL320 simplifies the visualization and measurement of gas emissions

WHAT IS THE MAXIMUM DISTANCE FROM THE LEAK SOURCE AT WHICH I CAN REPEATEDLY AND ACCURATELY USE THE QOGI METHOD?

The range and field of view (FOV) for the FLIR QL320 is dependent on the lens being used. These ranges are:

- 23 mm (24-degree FOV): 5 to 54 feet

- 38 mm (14.5-degree FOV): 8 to 90 feet

- 92 mm (6-degree FOV): 20 to 210 feet

The overall distance will affect the repeatability and accuracy of quantification results (similar to temperature measurement with a camera), as there are fewer pixels to utilize when calculating the gas leak’s concentration length from a greater distance. Accordingly, when using the FLIR QL320 at a greater distance, you will notice the plume extraction circle is considerably smaller.

WHAT IF I AM OPERATING IN A HAZARDOUS LOCATION AND CAN’T TETHER MY CAMERA TO THE FLIR QL320 IN THE FIELD?

A new feature available for use with the FLIR QL320 is Q-Mode. Q-Mode was originally designed for use with the FLIR GFx320, which is rated for use in Class 1, Division 2 hazardous locations when not tethered to the FLIR QL320. Q-Mode allows video sequences of leaks to be saved directly to the camera’s SD card and later post-processed in the FLIR QL320 — away from the hazardous location.

It remains advantageous to use the FLIR QL320 in the field, tethered directly to a camera, for several reasons:

- Knowing immediately whether you have a sufficient background temperature (ΔT)

- Obtaining real-time numbers on the severity of a leak and knowing if immediate action is required

- Utilizing features available on the FLIR QL320 while in the field, including Manual Sensitivity, Notch Boundary, and Variable Time Interval (1-sec; 5-sec; 60-sec), as well as determining leak rate unit options in real time

WHAT LIMITATIONS CURRENTLY EXIST WITH THE QOGI METHOD?

The current method qOGI is designed for point releases. Large, diffuse releases, such as those from a holding pond or a large tank seal, can be more difficult to quantify with this method.

Very large leak rates and very high exit velocities can be underestimated. High leak rates can incur the possibility of some saturation in the image, which will tend to underestimate the leak rate. For high exit velocities, it is possible the plume will not move enough to see the background behind the plume (required to calculate ΔT).

HOW IS THE QOGI METHOD BEING IMPROVED?

The optical gas imaging industry is heading toward quantification, and FLIR is leading development in this emerging field. Below are some recent improvements and new features for the FLIR QL320:

- Colorized gas plume overlay

- Capability to measure leak rate in concentration over pathlength (ppm-m)

- Ability to create multiple “notches” in the plume extraction boundary

- Single image snapshot with leak rate overlay

- Leak rate (rolling average) on video overlay

The improved FLIR QL320 interface

HOW IS THE CONCENTRATION OVER PATHLENGTH READING (PPM-M) DIFFERENT THAN A BASIC CONCENTRATION READING (PPM) YOU GET FROM A SNIFFER?

The QL320 gives concentration reading as a “concentration over pathlength” or “parts per million (ppm)” over the pathlength of one meter. This pathlength would assume the leak has a one-meter depth. In terms of X, Y, Z axis, the “meter” pathlength is the “Z” axis (depth) of the plume and NOT the “X” or “Y” (horizontal or vertical) axes. By definition, the reading would assume the leak seen is one meter in depth (from the initial leak, straight away from the camera).

If the depth is known (or could be estimated), average ppm across the depth can be calculated by dividing the ppm-m value by the depth. For example, if the QL320 gives a reading of 1,000 ppm-m and the plume depth is estimated to be 10 cm (0.1 m or ~ 4 in.), the average concentration in the 10-cm-deep gas plume is 10,000 ppm (1,000 ppm-m/0.1 m).

A sniffer or other device that presents data in ppm takes the reading from a sample of air molecules at a single point, and therefore does not require a pathlength reading. TVA devices also are limited in that they can measure a leak only if the device is pointed directly in the leak, which is more challenging, as this technology does not visualize a gas leak.

CONCLUSIONS

Quantitative optical gas imaging is effective, accurate, and convenient. Its merits are growing and its technological capability continuously improving. In addition to its obvious safety benefits over alternative gas quantification methods, qOGI offers cost-effectiveness as an add-on to existing OGI cameras and positions oil and gas operators to be at the forward-thinking edge of environmental consciousness in the communities where they operate.

The FLIR QL320 platform allows qOGI both in the field and, potentially, after a scan (post-process capability) with the Q-Mode feature and the tablet combination.

ABOUT THE AUTHOR

Craig R O’Neill has worked for FLIR for over 17 years and been actively involved in the OGI market since the introduction of commercial Optical Gas Imagers in June 2005. Currently, he has global responsibility for the Optical Gas Imaging line of business and the strategy for FLIR’s solutions in the oil and gas industry. In this role, he is the linking piece between customers, industry stakeholders, strategic partners and many vertically integrated aspects of the FLIR Instruments division including sales, marketing, engineering and product management. His goal is to ensure FLIR’s alignment to provide sensing solutions that meet the needs of the oil and gas industry.

ABOUT FLIR SYSTEMS, INC.

Founded in 1978 and headquartered in Wilsonville, Oregon, FLIR Systems is a world-leading maker of sensor systems that enhance perception and heighten awareness, helping to save lives, improve productivity, and protect the environment. Through its nearly 3,500 employees, FLIR’s vision is to be “The World’s Sixth Sense” by leveraging thermal imaging and adjacent technologies to provide innovative, intelligent solutions for security and surveillance, environmental and condition monitoring, outdoor recreation, machine vision, navigation, and advanced threat detection. For more information, please visit www.flir.com and follow @flir.

For more information about optical gas imaging please visit : www.FLIR.com/ogi