FLIR Arms Intelligent Power Inspection Robot with "Hot Eye"

A substation is a power facility for voltage change, acceptance and distribution of electric energy into a traditional power system. During substation operation, usually 95% of the information from inspections comes from visual observation. Although video monitoring is also often used to monitor substations, this technology cannot analyze the operational status of the target equipment, which leaves the possibility for safety issues. An Intelligent Power Inspection Robot equipped with thermal imaging cameras can however replace human inspection and effectively supplement remote signaling and remote viewing, thus ensuring the safe operation of substations.

Shenzhen Launch Digital Technology Co., Ltd. is a leading supplier of intelligent industrial equipment and solutions. The company’s Launch series of intelligent grid products has passed the comprehensive inspection from China’s Electric Energy Research Institute of the State Grid and from third-party inspection institutions. The products are successfully used in the Northeastern Grid, the Northwestern Grid, the Northern China Grid, the Central China Grid, the Eastern China Grid and the Southern Grid. Launch’s substation robots are mainly used for substations of 110kV, 220kV, 330kV, 500kV and above, replacing workers to carry out visual inspections, and effectively improving the frequency, efficiency and quality of inspections.

Temperature of power equipment

According to Mr. Xian Kaiyi, a Launch Technology expert, one of the critical factors during the temperature measurement of power equipment is that abnormal temperatures indicate a looming equipment failure. Thermal imaging can be used to detect such equipment failures because this technology is an ideal non-contact tool to capture heat radiation and thus temperature changes.

Human routine inspections usually take into account main substations, isolators, switches, and other equipment, as well as the status of foreign matter within a substation. However, human inspection can be cumbersome, repetitive and monotonous, and thus prone to mistakes. Robots don’t have these problems of course. The Intelligent Power Inspection Robot from Launch is able to perform high-frequency, large-scale and error-free inspections. The robot uses a thermal imaging camera from FLIR Systems to accurately examine the heating of transformer’s windings and oil-cooling systems, HV breakers, isolators, capacitors, and bus bars, and to locate thermal defects and provide alarms, all of which improve equipment inspection efficiency significantly.

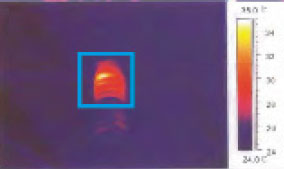

Digital image and thermal image of a substation, showing an overheated transformer

Temperature alarms

The intelligent inspection robot performs daytime inspections, nighttime inspections with thermal imaging and inspections of key equipment. It uses multi-sensor locating technology, coupled with electric map and path planning to monitor the robot’s navigation and motion control. This helps to accurately obtain equipment status and it improves the accuracy and reliability of the video analysis.

The inspection robot makes use of a FLIR A310 thermal camera. The robot will shuttle between power equipment, either automatically or manually, save all recorded inspection information and generate analysis reports. In case of a temperature anomaly or electric closure, the whole system will set off an alarm immediately and locate the source of the failure.

Thermal imaging provides robot with “Hot Eye”

“The core components of the intelligent inspection robot are the FLIR thermal imaging camera and the visible light camera. Both are installed on the top of the robot, like a sensitive eye,” Mr. Xian Kaiyi explains.

The temperature measurement data is sent to the main control unit, via Ethernet and via the video compression board, providing multi-frame full-screen temperature measuring data and information for the highest and lowest temperatures. At the same time, radiance, distance and area information are obtained, in combination with an accurate preset position. This way, the measurement accuracy can be ensured and temperature measurements can be compared continuously.

Seamless compatibility

According to Xian Kaiyi, the integration of thermal imaging data and data acquired from other sensors is critical. “Effective compatibility between the FLIR data and robot software was achieved, which was a critical factor for success.”

FLIR thermal cameras are installed in the robot, track, and fixed support, and they work perfectly with the high-definition camera, audio acquiring equipment and Wi-Fi equipment, ensuring the safe operation of power equipment in the workplace with a precise temperature measurement within a tolerance of ±2ºC.

Thermal imaging camera for critical equipment monitoring

Mr. Xian Kaiyi commented: “The FLIR A310 thermal camera was the ideal fit for our intelligent substation inspection robot.” The A310 is a fixed-mounted thermal imaging camera, which can be installed almost anywhere to monitor critical equipment or other valuable assets. The FLIR A310 has built-in analysis functions, like spot temperature measurement, area temperature measurement, and difference temperature measurement. The FLIR A310 is Ethernet/IP and Modbus TCP compliant, so analysis and alarm results can easily be shared to a PLC. The camera automatically sends analysis results, IR images and more as an e-mail on schedule or at alarm. The FLIR A310 produces crisp thermal images of 320 x 240 pixels, can stream MPEG-4 video over Ethernet to show live images on a PC and comes with a built-in 25° lens with motorized focus.

Reliable partner

Mr. Xian Kaiyi: “The support provided by FLIR for the integration of the thermal camera into our system is noteworthy. FLIR provided us with all the necessary information. This reflects the reliability and trust of a big brand within the industry.”

“Most critically, FLIR products have quality imaging, ±2ºC accuracy, availability of real-time analog images and full-screen temperature measurement data. More specifically, the FLIR A310 allowed us to reduce the workload of our workforce, reduce subjectivity which is typical of human inspections, and increase our inspection frequency. Combined with the system software, the FLIR camera is able to locate problems and generate reports automatically, which improves inspection efficiency and operational safety.”